Sound deadening materials are crucial for enhancing comfort and safety in enclosed spaces by absorbing and dissipating noise. Automotive bodywork leverages advanced fabric-based alternatives for seamless integration and improved performance. Recent trends focus on eco-friendly options like recycled materials and plant-based composites, addressing environmental concerns while maintaining structural integrity. When selecting sound deadening solutions, consider both performance (like low-frequency sound blocking) and practicality, such as moisture resistance and ease of installation, balancing traditional materials like fiberglass with versatile fabric options.

In today’s world, effective sound deadening solutions are essential for creating peaceful living and working spaces. While traditional foam and fabric materials have long been the go-to options, a growing market of alternatives is emerging. This article delves into the realm of sound deadening, exploring various materials and their performance. We’ll dissect the basics of conventional options, examine innovative alternatives like natural fibers and aerogel, and provide a comprehensive analysis to help you choose the best sound deadening solution for your needs.

- Understanding Sound Deadening Materials: The Basics

- Exploring Alternatives to Traditional Foam and Fabric

- Comparative Analysis: Performance and Practicality of Sound Deadening Solutions

Understanding Sound Deadening Materials: The Basics

Sound deadening materials are designed to absorb and dissipate sound waves, thereby reducing noise levels within enclosed spaces. This is particularly important in environments where excessive noise can be detrimental to comfort and safety, such as automotive interiors or recording studios. The primary goal of these materials is to create a quieter space by blocking or muffling unwanted sounds.

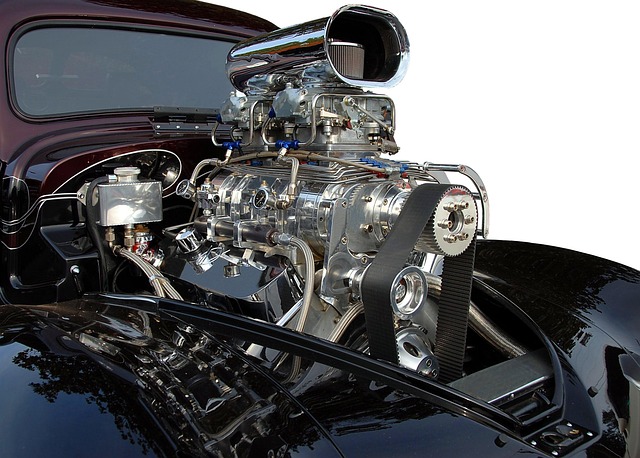

In the context of car bodywork services, sound deadening solutions have evolved beyond traditional foam to include fabric-based alternatives. Paintless dent repair techniques often incorporate advanced sound-absorbing fabrics that seamlessly integrate into vehicle designs. These innovative alternatives not only enhance acoustic comfort but also contribute to improved structural integrity and better overall performance, especially in comparison to conventional foam options.

Exploring Alternatives to Traditional Foam and Fabric

In recent years, there has been a growing interest in exploring alternative sound deadening materials beyond traditional foam and fabric. This shift is driven by both environmental concerns and the desire to offer more sustainable solutions for various applications, including automotive body work, automotive restoration, and autobody repairs. Natural and eco-friendly materials are now being developed and tested to meet the same performance standards as conventional options, but with a reduced environmental impact.

One such alternative is using recycled materials, which not only reduces waste but also offers excellent sound absorption properties. Other innovative solutions include acoustic panels made from plant-based composites, offering both structural integrity and superior noise reduction capabilities. These advancements are particularly beneficial for those involved in automotive restoration projects, where achieving optimal interior quietness without compromising aesthetics or durability is essential.

Comparative Analysis: Performance and Practicality of Sound Deadening Solutions

When comparing sound deadening solutions, it’s crucial to consider both performance and practicality. Sound deadening materials like fiberglass and rockwool excel in blocking low-frequency sounds effectively, making them ideal for automotive applications where noise reduction is paramount, especially in vehicle body shops and during bumper repairs. These traditional options offer excellent value for money and have been proven over time, with a long lifespan and resistance to moisture damage.

However, fabric alternatives like acoustic foam and custom-fitted fabrics are gaining popularity due to their versatility and aesthetics. While they might not match the rigid materials in terms of sound absorption at low frequencies, these flexible options can be molded around complex vehicle shapes, providing an elegant solution for odd spaces. Moreover, fabric treatments and innovative composite designs offer improved durability and easier installation, appealing to DIY enthusiasts and vehicle owners looking for scratch repair solutions without professional help from a bustling workshop.

In conclusion, the choice of sound deadening materials depends on specific needs and preferences. While traditional foam and fabric offer effectiveness, alternatives like natural fibers, acoustic panels, and innovative composites provide eco-friendly and aesthetically pleasing options. A comprehensive understanding of each material’s performance and practicality is key to selecting the best solution for any space, ensuring optimal noise reduction without compromising style or sustainability.